HPNow HPGen A-Series

HPNow offers advanced HPGen technology for on-site hydrogen peroxide generation, reducing the need for transportation and handling of hazardous chemicals, and guaranteeing direct access to supply of this essential cleaning and oxidising agent, ensuring your irrigation and hydroponics systems are always optimised and operational.

HPGen is uniquely designed to address the needs of the horticulture sector. It produces hydrogen peroxide (Peroxide UltraPure™) directly on site, in a completely safe and autonomous manner, HPGen helps growers protect crops against water-borne pathogens, improve crop health, elevate dissolved oxygen levels, improve irrigation uniformity, decreases upkeep of the irrigation system and increases its longevity. Peroxide UltraPure™ leaves no undesired traces – no chemicals are introduced or required that may adversely influence plants or soil. Furthermore, no stabilizing materials, metals or disinfection by products are left behind.

The HPGen A-Series system runs automatically, and no user intervention or operation is required. Water, power and air are the only required ingredients. The system can be continuously monitored remotely via a cloud-based application to ensure optimal operation.

Built to run for applications demanding hydrogen peroxide from 1 kg per day and up to 3 kg per day, the HPGen A-Series is fully contained in a compact cabinet with a relatively small footprint. Ideally suited for water treatment for greenhouse irrigation, hydroponic systems, and aquaculture, HPGen eliminates bio-foul and bio-films in drip irrigation lines, improves irrigation uniformity, and reduces irrigation system maintenance.

The HPGen A-Series is specifically designed for quick and easy installation, and requires minimal on-site maintenance. The system is also scalable and the number of hydrogen peroxide production ‘stacks’ can be quickly expanded, should future production demand require it.

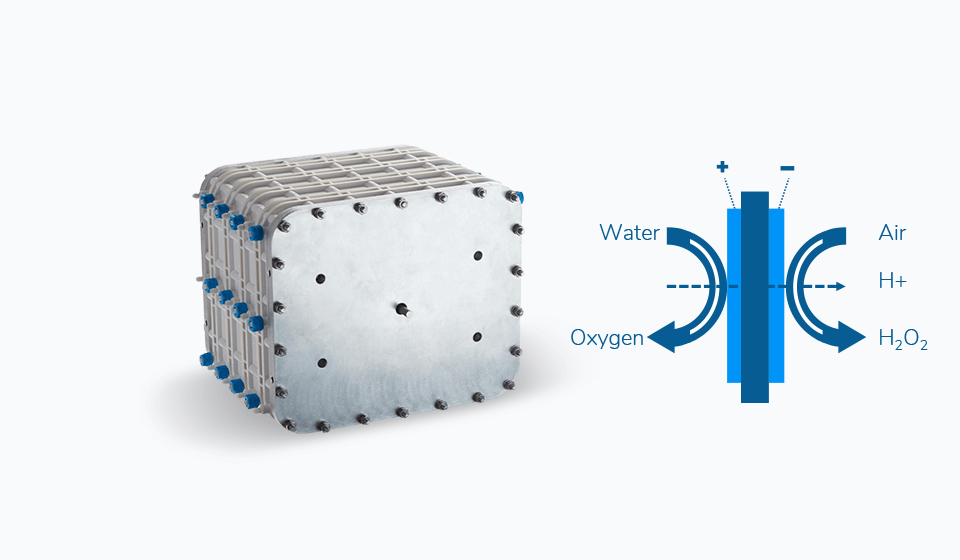

HPNow’s breakthrough oxygen reduction technology enables record-high efficiencies, and the proprietary air and water management system enables the production of safe, low concentration hydrogen peroxide solution using only electricity, air, and water. No gaseous hydrogen or vaporized water inputs are required, and the electrolyte is in membrane form, negating the need to handle liquid electrolyte.

Suitability:

- Controlled environment agriculture (CEA) facilities

- Commercial grow operations

- Greenhouses and nurseries

- Vertical farming

- Drip line systems

- Irrigation systems

- Spray systems

- Hydroculture

- Hydroponics

- Gutters

Features:

- Autonomous, on-site operation

- Increases oxygenation

- Uniform irrigation

- Safe, consumable-free – no chemical inputs

- Leaves no unwanted trace

- Helps to keep crops protected

- Protects against water-borne pathogens

- Eliminates biofilms

- Hydrogen peroxide breaks down into water and oxygen, increasing oxygenation levels in the water and root zones

Real Industry Expertise

Don't be surprised to see the odd PhD knocking around our office. When you work with Vertikit you are choosing actual leaders of the field. We've got years of research experience and practical project knowledge to share.

Our Unique Approach

With our level of experience comes the ability to be really creative when it comes to product choices. Our curated product catalogue comes from the world's best suppliers of the specific technologies you need to succeed, regardless of whether they are farm-specific.

Features

Why Choose Vertikit?

Why Choose Vertikit?

Prepared for anything. Our collective history of working with both growers and industry means that whatever the size or complexity of your operation we'll have you growing in no time.

No bias and no bull. You'll always get a straight answer from our team on your best options, regardless of manufacturer.

Vertikit source from many industries, we love to mix and match the best tech from a wide range of innovators from around the globe (yes, globe - we're scientists remember).